East Sussex Finescale

Lighting in your Track

Room

LED fluorescent tube replacement

and how the

re-wiring circuit works!

Certainly amongst the East Sussex Finescale group most

of us use fluorescent strip lighting in our trackrooms. Whilst fluorescent

tubes are likely to be around for many years to come LED tubes are now becoming

widely available. In this respect many of our group are looking to utilise this

new technology.

Essentially it appears there are two basic types of fluorescent light fittings:

1.

‘Old

style’ fluorescent light using starters.

2.

‘Modern

style’ fluorescent light using electronic ballasts.

Fluorescent lamps using electronic ballasts needing

internal wiring modifications to accept LED tubes.

Moving

to LED Technology

Firstly, any mains electrical wiring should be

undertaken and signed-off by a qualified electrician; this page is not a wiring

instruction – merely an explanation as to why a wiring circuit is designed the

way it is. If you need instructions for electrical wiring then please consult a

qualified electrician and their accredited supplier.

The track room mainly uses 4’ T8 high-frequency

‘daylight’ fluorescent tubes and fittings; half of which are located above and

to the rear of the railway baseboards. Whilst tube-changing is straightforward,

if one of the high-frequency electronic ballasts failed it would be a struggle

to reach and replace.

With the advent of LED tubes, the decision was

taken to replace those fluorescent tubes located above baseboards with LED

types, this negating the future need to replace the electronic ballasts if ever

they failed.

A trial was undertaken with replacement of a

single tube. The result was far more impressive than expected, particularly in

terms of the much-improved quality of light from the LED tube. Accordingly, the

decision was made to replace all the fluorescent tubes (twenty-six in all).

Whilst the capital outlay is significant the

overall power consumption of the track-room’s lighting will also be halved from

900 watts to 450 watts.

ESF

debate

However, the rewiring for the light fittings (fluorescent

to LED) was slightly puzzling as there appears to be different wiring diagrams

promoted. Some of these diagrams meant the LED tube could only be fitted in one

direction; a dead short might be created if it wasn’t – as a qualified safety

professional (including industrial electrical engineering) this did not sit

comfortably.

Seeking to understand, this led to much debate

within East Sussex Finescale and an interesting

exchange of views. However, ultimately with a qualified electrician on-site (and

explanations found) others might be interested in the ‘why’ behind the circuit

used to re-wire the fluorescent light fittings in the track-room.

‘Old

style’ fluorescent light

(using starters)

The T8 replacement LED tubes each come with a

replacement unit for the starter. You simply replace the lamp’s starter and

tube and that should be that. Your lamp is now an LED fitment.

Accordingly, conversion to LED tubes should be

simple and straightforward without any wiring changes required in the light

fitting.

‘Modern

style’ fluorescent light

(using high-frequency electronic ballasts)

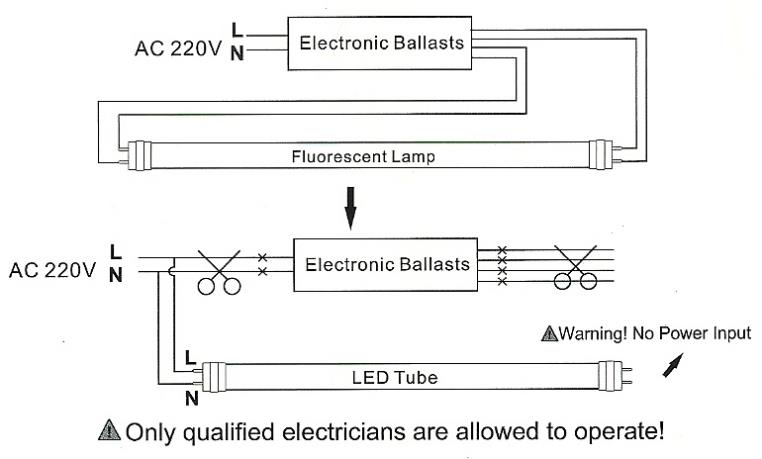

These need to be rewired and the high-frequency

electronic ballasts removed from circuit (if not from the light fitting). In

the track room it was simpler to have these taken out of circuit (disconnected)

and just leave them in the light fitting. The rewiring needed a new terminal

block fitted and a new 24” length of single core wire. As stated previously, a

qualified electrician will do this for you.

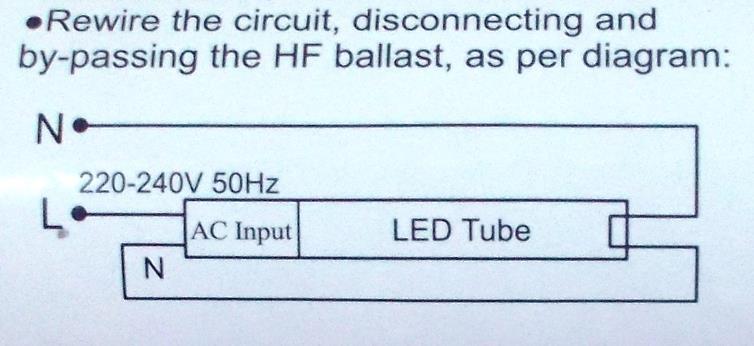

However, the circuit diagram for the LED tube

intrigued, leading towards wanting to understand exactly how it worked; particularly

as three of the LED tube’s pins appeared to be wired into the same circuit. In

reality it is slightly cleverer than that.

Manufacturer’s wiring both-ends

fed diagram

The Live feed enters the left-hand fitting (which

holds the tube’s left-hand end). In the diagram above this enters the LED

tube’s Input unit (as shewn above). However, there is a ‘link-wire’ that

carries the Neutral along the length of the LED tube into the right-hand

fitting (which holds the LED tube’s right-hand end).

The Neutral feed enters the right-hand fitting

which holds the LED tube’s right-hand side end. At the ‘non-input’ end of the

LED tube (as shewn above) the LED tube’s two pins are (internally) directly

connected together thus ensuring the Neutral is connected through to the LED

tube’s Input unit.

The LED tube will illuminate!

So why is

this circuit needed?

This circuit enables the LED tube to be

reversed; that is inserted with the Input end on the right-hand side (the other

way around to the diagram above).

As shewn above, the Live feed enters the

left-hand fitting (which holds the tube’s left-hand end). However, with the LED

tube reversed the Live feed simply connects across to the second pin and the ‘link-wire’

now carries the Live (not Neutral) along the length of the LED tube into

the right-hand fitting (which holds the LED tube on the right-hand side) and into

the LED tube’s Input unit.

The Neutral feed enters the right-hand fitting (which

holds the LED tube’s right-hand end). This means the Neutral is now connected directly

to the LED tube’s Input unit.

The LED tube will illuminate!

In summation

i.

the

LED tubes use bridge-rectifiers from the AC mains input;

ii.

the

‘link-wire’ will be Neutral if the LED tube is inserted with the Input-end to

the left;

iii.

the

‘link-wire’ will be Live if the LED tube is inserted with the Input-end to the

right;

iv.

the

LED tube can be inserted either way round!

So why

not just connect the Live and Neutral to one fitting-end?

If both the Live and neutral were connected to

the left-hand fitting (which holds the tube’s left-hand end) the tube would

work provided the LED tube has been inserted with its Input at that end. Some manufacturer’s

diagrams portray this arrangement.

Manufacturer’s wiring single-end

fed diagram

However, if the tube is fitted the ‘wrong-way

round’ then a dead-short will be created. The is because the other two pins of

the LED tube are directly connected together.

Placing an LED tube into a light fitting thus

wired would mean the installer will need to know:

a)

Which

end of the light fitting is ‘live’ &

b)

At

which end of the LED tube is its Input (some are clearly marked).

Ultimately

consult a qualified electrician!

Fluorescent light fittings using high-frequency

electronic ballasts should be rewired by a qualified electrician. However, at

least now the modeller can understand the reasons for this interesting piece of

circuitry.

Return to East Sussex Finescale’s home page

Link to BloodandCustard modelling

pages

ALL

PHOTOGRAPHS ARE COPYRIGHT